Installation and Maintenance of Cardan Shaft

The installation of Cardan Shaft

Attention points for installation of Cardan shafts:

- Cardan drive shaft is delivered as a whole assembly, so there is no need for disassembly and washing before installation.

- Hoisting Cardan shaft should be carried out in a horizontal state, and its lifting should use hemp rope or nylon rope.

- The forkhead at both ends of the spline shaft and spline sleeve should be in the same phase.

- The anti-rust paint, grease, rust, and dust on the flange mounting surface shall be cleaned.

- Flange connection bolts can only be put in from the flange side matching the crossed drive shaft, and the nut is tightened by the flange side of the Cardan drive shaft.

- Flange connections shall be made with grade 10.9 high strength bolts and grade 10 nuts.

- Apply a small amount of MoS2-free grease to the threaded portion of the bolt before the nut is screwed into the bolt.

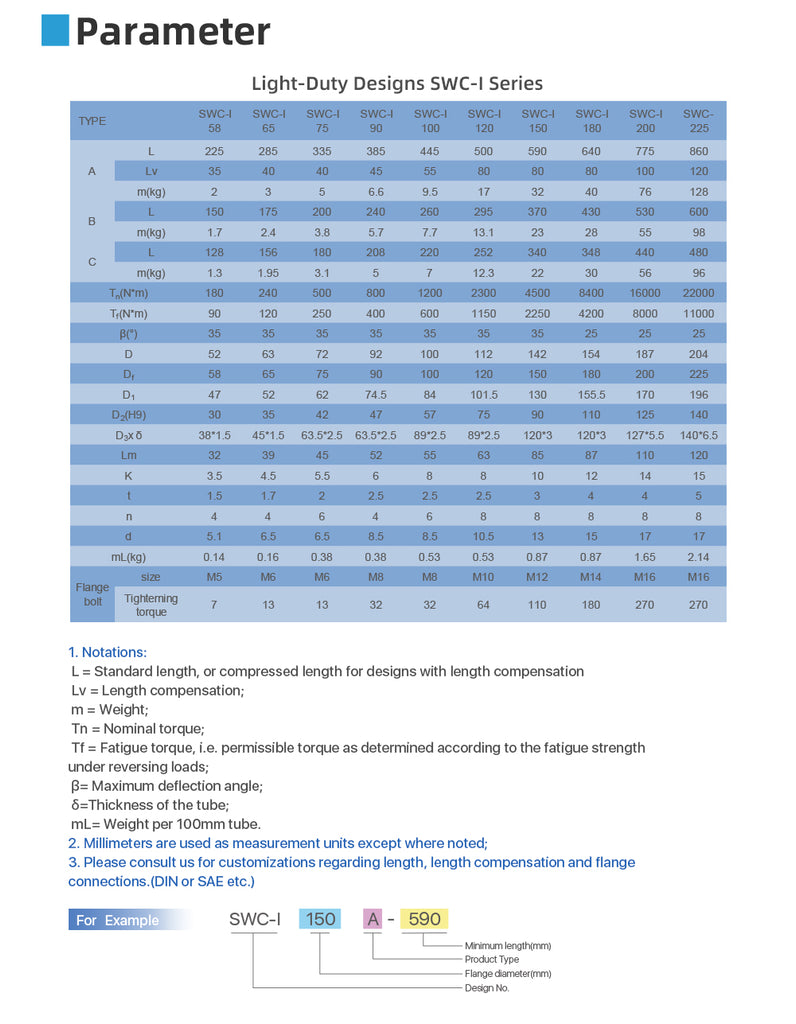

- The connection bolts shall be symmetrical in accordance with the required pre-tightening torque and uniformly tightened with a torque wrench. The relevant connection and pre-tightening torque shall conform to the following table.

The maintenance of the Cardan shaft

- Check

Checking whether there is any abnormality in the running of Cardan drive shaft can not only ensure safety but also improve the operation rate of mechanical equipment, which is also beneficial to extending the service life of drive shaft. If any abnormality is found, stop operation immediately to find out the cause. The crossed drive shaft coupling in normal operation shall be serviced every six months. The items to be examined are as follows:

- A) Check the wear condition of cross pin shaft journal, bearing outer ring and short cylindrical roller surface, measure its radial clearance, observe whether the contact surface has an indentation, pitting, peeling, cracking, and other phenomena.

- B) Check whether the spline shaft slides flexibly. When spline teeth are worn, distorted, or have excessive fit clearance, replacement or repair shall be carried out.

- Lubricate

Bearings and spline shall be lubricated periodically. Except for the operation, the oil shall be injected once a week within six months, and once every half a year after the working conditions are stable. For the spline shaft and the universal coupling shaft used for the main drive of the mill, the oil is injected every three months. The new oil should be used to squeeze out from the t-type oil seal until the new oil spills out ( normally 2# lithium base fat or 2# molybdenum disulfide calcium base fat ).

To ensure the safe operation of universal coupling shaft, avoid the situation that the end of the connection is stuck, causing the cross bag to twist off and fly out to hurt someone, the spindle connected with the cross pack must be fully lubricated, spindle bearing must be replaced regularly and install safety cover on both flange forks if necessary.

- Maintain

If abnormal sound, vibration, oil leakage, and other abnormal phenomena are found, the decomposition inspection should be stopped as soon as possible. Periodic inspection should be carried out even if no abnormality is found, especially for Cardan shafts, which are used in important parts and continuously for a long period of time and cannot be stopped in the middle process. The standard time is 5000 hours or one year, and the specific time should be determined according to the use conditions.

- A) Disassemble

Dirt and oil should be removed from the Cardan drive shaft when disassembling, and external foreign matter should be prevented from entering the bearing and spline. Prior to disassembly, use white paint to mark all joint parts, bearings, cross shafts, and other parts to prevent misalignment during assembly.

- B) Clean

Bearings and cross shafts can no longer be cleaned in the same oil tank of other parts, and compressed air is used to dry them after cleaning.

- C) Check

After decomposition, the main parts should be carefully checked for wear and tear and replaced according to the extent. Check for spalling, pitting, abrasion and indentation on the cross shaft and rolling surface. Replace if found.

- D) Assemble

When assembling, proceed in the opposite order of disassembly and follow the white mark to make the total position exactly the same before disassembly. The forkhead at both ends of the spline shaft and spline sleeve should be in the same phase; ensure the axial clearance of the single side of the cross axis from 0.05 to 0.10mm; connection bolts shall be pre-tightened with torque wrenches in accordance with the pre-tightening torque specified; After assembly, re-lubricate its bearings and spline again.